Step 1 - LO-End :-

-

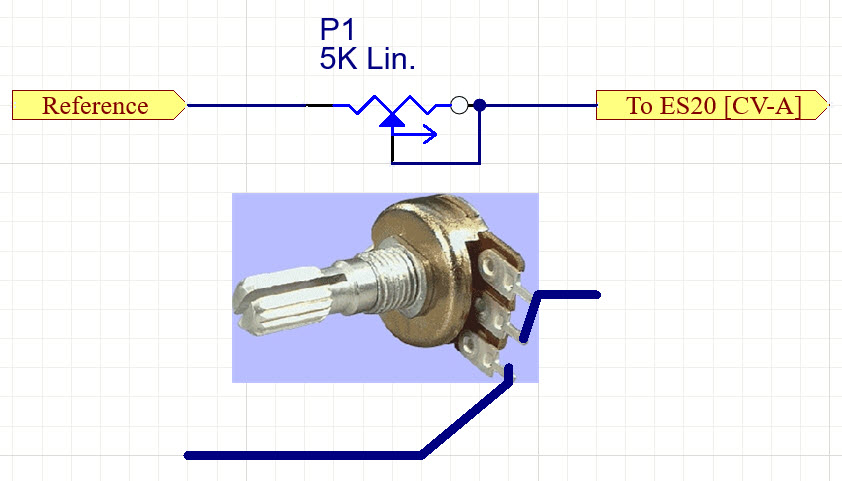

Set the '5K Lin' pot fully anti-clockwise

-

Set [FREQUENCY], [WAVE SHAPE] and [CV A] to their minimum (CCW) position

-

Set [CV B] to ‘0’

-

Monitor [SAW-DC]

-

Adjust P101 for an output of 16Hz

Step 2 - Wave Shaper :-

-

Set P201 to its mid-position

-

Monitor [SHAPED DC]

-

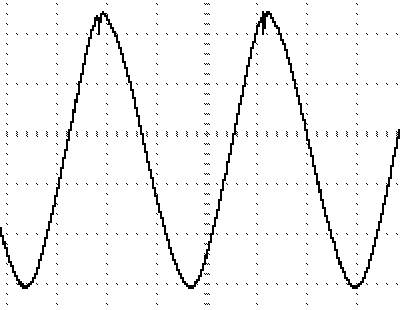

Adjust P201 for best sine shape which should be similar to that in Figure B. Note that the wave shaping circuitry can take a couple of seconds to stabilise so make small adjustments and wait for the waveform to stabilise

-

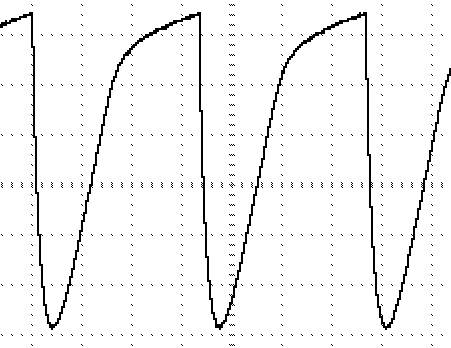

Turn [WAVE SHAPE] to maximum and check that the waveform is similar to that in Figure C

-

Repeat steps (3) and (4) until both ends of [WAVE SHAPE] are a best match for those in Figures B & C

Figure B

Figure C

Step 3 - HF Trim:-

Stage 1:

-

Monitor [SAW DC]

-

Set [CV-B] pot to '0'

-

Set REFERENCE to 0.0V to [CV A]

-

Adjust [FREQUENCY] for 300Hz using [CV-B] pot for fine tuning

-

Set REFERENCE to 2.0V to [CV A]

-

Adjust ‘5K Lin’ pot for 75Hz

-

Repeat steps (3) to (5) for best accuracy

Stage 2:

-

Set REFERENCE to 2.0V to [CV A]

-

Set [CV-B] pot to '0'

-

Adjust [FREQUENCY] for 300Hz using [CV-B] pot for fine tuning

-

Set REFERENCE to 0.0V to [CV A]

-

Adjust P102 for 1200Hz

-

Repeat steps (1) to (5) for best accuracy

Calibration of the HF Trim is a series of successive approximations so stages 1 and 2 should be repeated several times for optimum accuracy.