|

Studio

System |

The Studio System series offers the user a flexible solution to their EuroRack/EuroSynth enclosure needs.

Using a small set of building elements the user can build systems from 42HP wide through to 168HP.

End Cheeks allow multiple enclosures to be joined to provide 6U, 12U and 18U systems.

The Studio 500 profile is ideal for the desktop or studio environment with its 22 degree sloped panel face allowing tall systems to be fitted in to the minimal footspace while maintaining optimum user access to all of the panel controls.

The Studio 700 enclosures are 110mm deep (90mm internal module depth) and provide a shallow-profile design ideal for where space is small or a portable solution is required.

The Studio 300 have been designed to be used as a lid for all of the Studio Series of enclosures.

The 65mm depth allows patched systems to remain patched during transport.

The Studio 300 can also be used as a skiff with a nominal internal depth of 42mm internal module depth*

for where space is critical or a truly portable solution is required.

* This depth assumes that our ED7xx busboards are fitted. If not fitted, then the depth increase to 51mm

In cases wider than 42HP, it is possible to have 'empty' sections (each 42HP wide) where you have approximately 60mm available depth

|

|

|

|||||||||||||||||||||

|

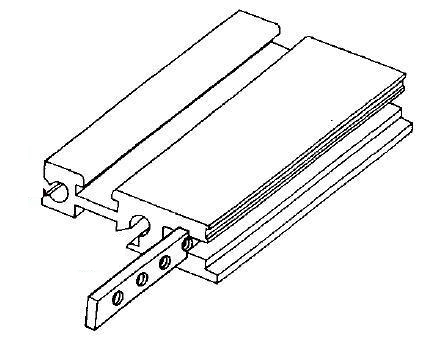

Rails Rails form the main component of any racking system by providing a mechanical sub-frame for securing modules in to your system. 4 Rails are required for each 6U section of subrack and come in the following standard `module opening' widths:- 42HP, 84HP, 126HP and 168HP. Other widths are available on request. Made from

a high-quality aluminium they are irridium plated for improved

electrical conductivity All Rails

are pre-tapped to accept M5 bolts making assembly a breeze

while offering a secure and rigid assembly. |

|

|||||||||||||||||||||

|

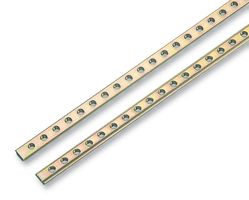

Tapped Strips slide in to a dedicated slot near the front of the rail and are used to accomodate the module fixing screws. The strips are tapped at 1HP (5.08mm/0.2") intervals with 3.0mm holes (2.5mm Tapped Strips available while stocks last). Maximum strip length is 84HP but their design allows them to be butted end-to-end with no loss of the 1HP interval. We also offer 19HP, 42HP and 83HP Tapped Strips allowing the common system widths of 42HP, 84HP, 104HP 126HP and 168HP to be easily accommodated without requiring Tapped Strips being cut. For those

requiring flexibility over the spacing between tapped holes

such as when installing modules that do not confirm to the

standard defined by Doepfer and as used in our Panther family,

we offer Square Rail Nuts. These slide in to the same slot

as used by the Tapped Strips and can be positioned anywhere

along the length of the rail.

|

|

|||||||||||||||||||||

|

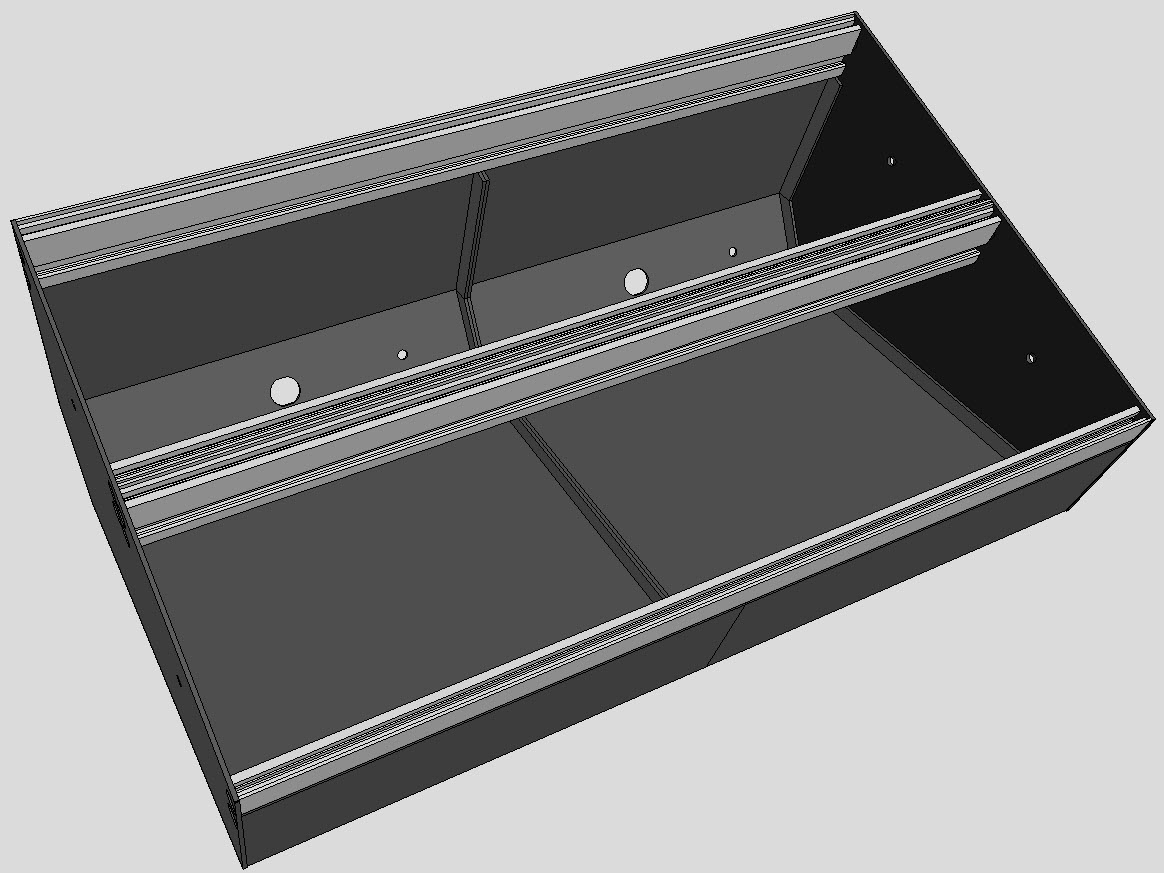

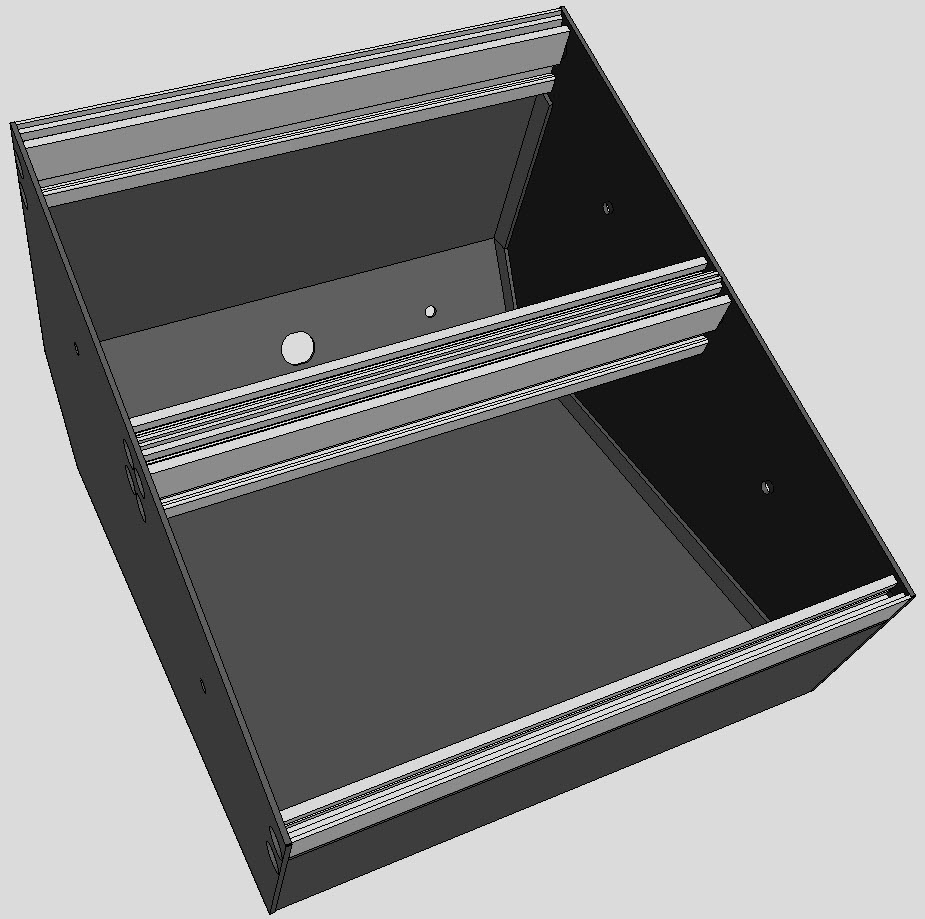

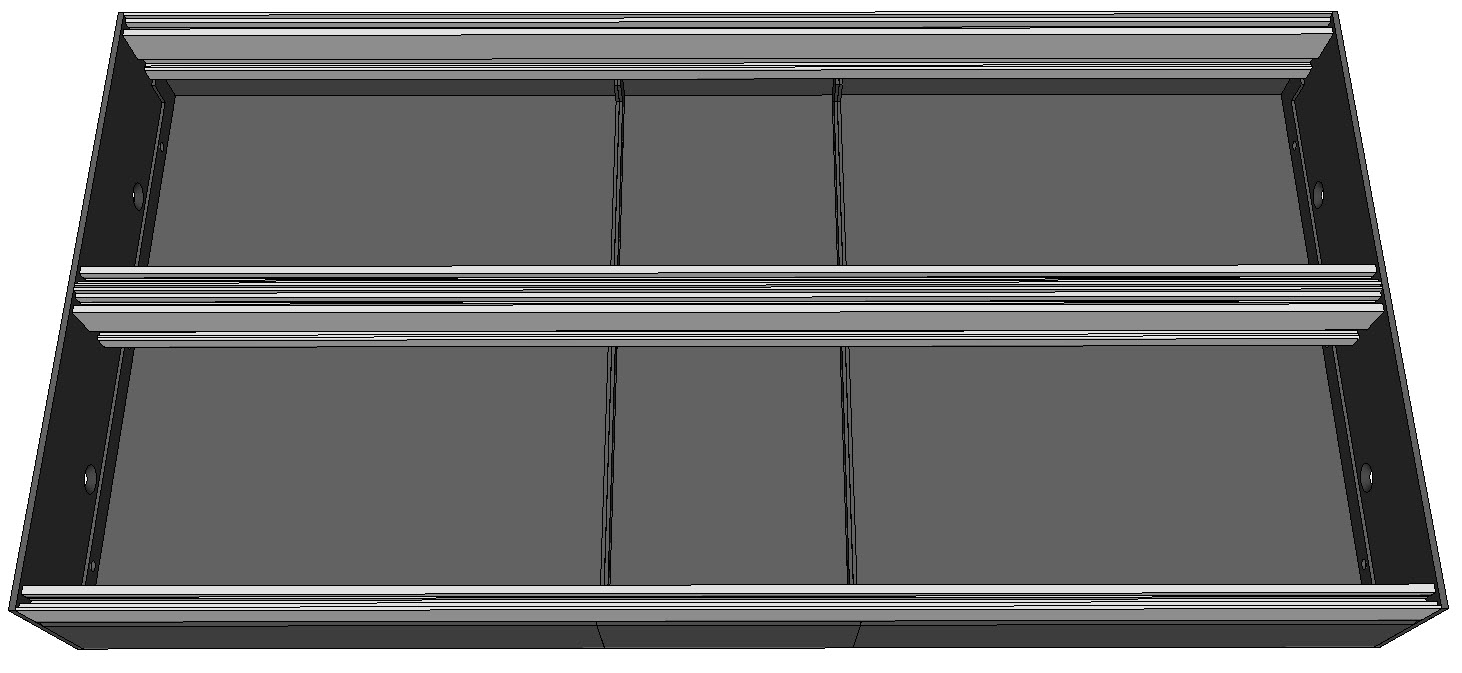

6U 42HP Skins - Studio 500 Our 42HP

6U 500 Skin is a new approach to subrack construction.

The front section will accomodate modules with a maximumdepth of around 80mm Each Skin is supplied pre-fitted with a series of M4 threaded studs in the base that match our Busboard Carrier Plate. The plates, which are pre-punched to provide support for our ED1xx family of busboards, provide a common mounting template for case manufacturers requiring only 4 fixing points in the case. The stud pattern in the 42HP Desktop Skin allow the carrier plate (and hence busboard) to be mounted in one of 3 positions providing the builder with flexibility in the position and number of busboards installed in to a system. Each Skin also has a cut-out in the rear to accept a multipole power connector which offers an easy means of getting power in to your system without having to drill holes as an alternative to our Power Panels. It also allows power to be fed from one boat to the next. |

|

|||||||||||||||||||||

|

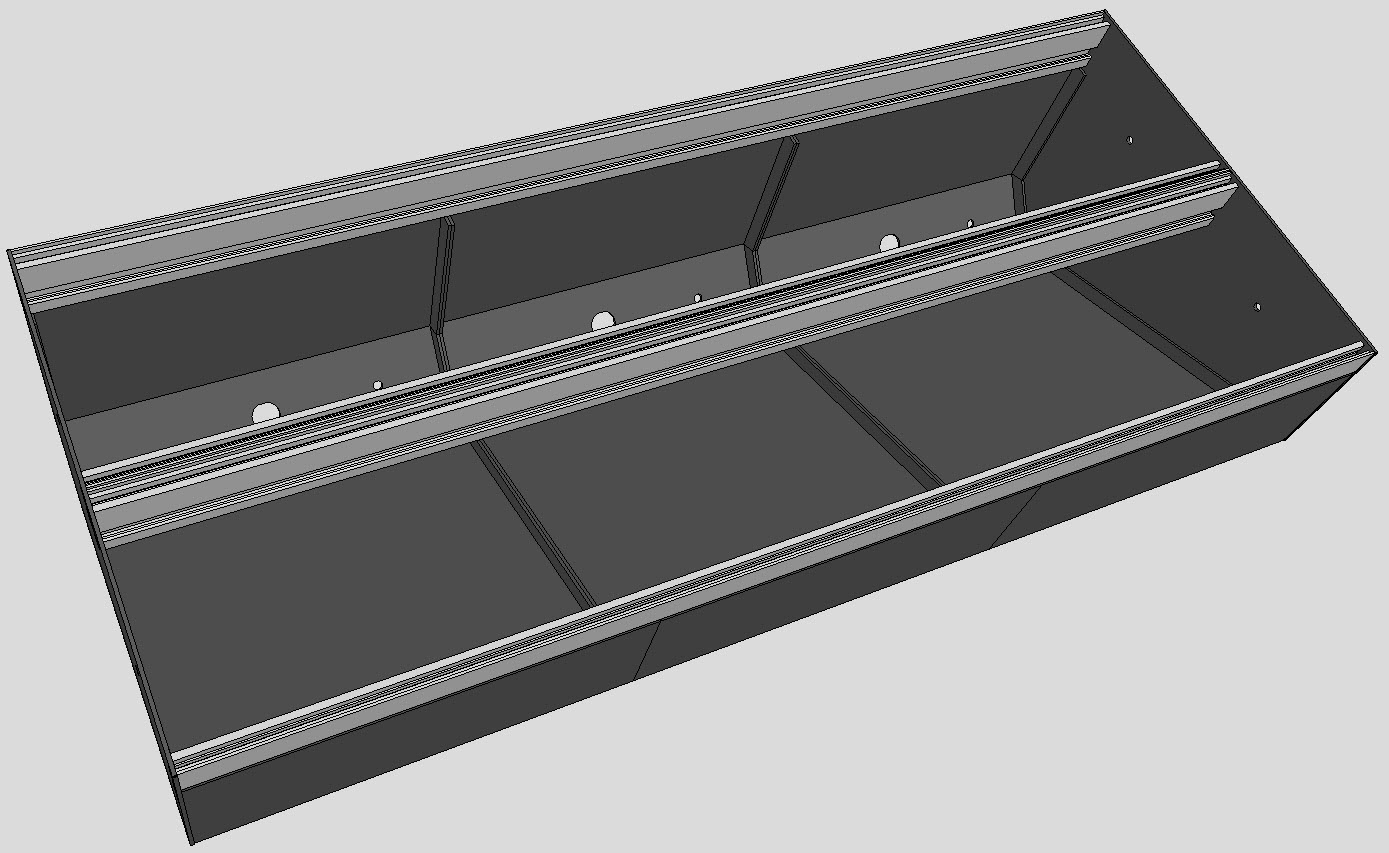

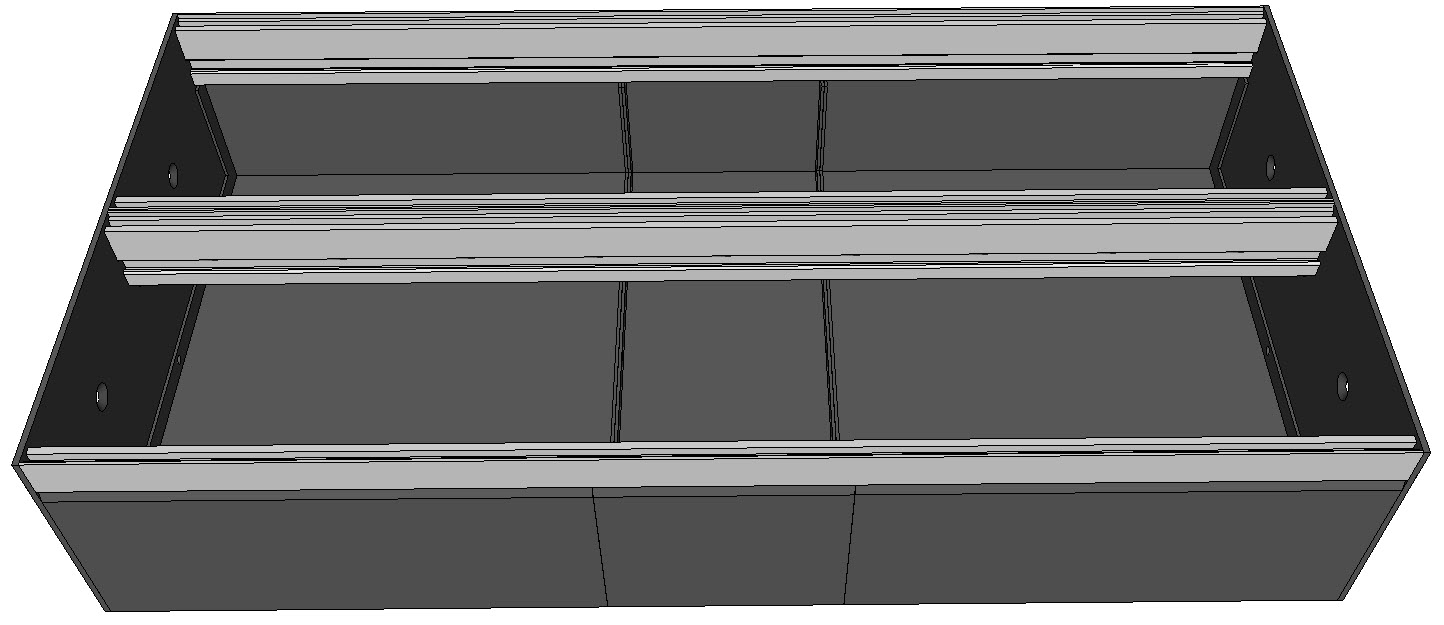

6U 42HP Skins - Studio 700 Our 42HP

6U 700 Skin is a new approach to subrack construction. The Studio 700 will accomodate modules up to a depth of 90mm Each Skin is supplied pre-fitted with a series of M4 threaded studs in the base that match our Busboard Carrier Plate.The plates, which are pre-punched to provide support for our ED7xx family of busboards, provide a common mounting template for case manufacturers requiring only 4 fixing points in the case. |

|

|||||||||||||||||||||

|

6U 42HP Skins - Studio 300 Our 42HP

6U 300 Skin is a new approach to subrack construction. Each Skin is supplied pre-fitted with a series of M4 threaded studs in the base that match our Busboard Carrier Plate. The plates, which are pre-punched to provide support for our ED7xx family of busboards, provide a common mounting template for case manufacturers requiring only 4 fixing points in the case. Studio

300 Assembly Guide The Studio 300 was actually designed to be a lid for the Studio 500 and Studio 700 and the depth of the Studio 300 allows for most patch settings to be retained while in transit. To use the lid requires both the Studio 300 and the associated boat to have our End Cheeks fitted. |

|

|||||||||||||||||||||

|

Fixing Hardware Assembly of all of our Studio x00 Series is done using bolts making them an easy assembly for everyone. All the required hardware is supplied with our Studio x00 Series

Kits but can also be

supplied loose for those purchasing their own mix of parts. |

|

|||||||||||||||||||||

|

End Cheeks We offer End Cheek Profiles for all of our Studio x00 Enclosures that provide both a cosmetic appealing finish to your system and also protect your work surface from scratches and scuffing by incorporating small feet that lift the whole unit approximately 2mm above the worksurface. Each End Cheek is 19mm thick affording a rigid end piece that will not buckle or bend and has 2x M5 blind nutserts for each 6U section that mates up with fixing points on the 6U Skin End Plates. The End Cheeks are made from a high quality pure white thermoplastic that offers the following features:-

Many systems will require more than 1 boat to achive the desired module capacity or to allow a sub-set of the system to be taked away and used for live performances or playing with other users/systems. We offer a couple of solutions to assist with multi-boat installation:- 1) Studio Master, and The Studio Master comprises 2 End Cheek profiles :-

The Tower-End Cheek has two orientation modes:-

These 2 profiles let you build 6U, 12U and 18U systems with the 18U system having a removable 6U section ideal for taking a part of your system on to the road or around to a friends place. The Studio Tree offers a more flexible solution that utilises a carrier frame (Tree) that allows multiple boats (complete with their associated End Cheeks) to be 'connected' together. By using a simple Thumbwheel assembly, a Studio Tree system can be quickly disassembled, transported and re-assembled without the need for additional tools

|

Studio Master

Studio Tree |

Configured Systems

Below is a table of a few typical powered system configurations (with recommended minimum* power and distribution options).

The examples show Studio 500 and Studio 700

and these can be interchanged as required.

The lists include a 4HP Power Panel but this may be omtted and a rear mounted POWER IN connector fitted instead.

*dependent on total module loading - may require an ED704 be replaced by an ED705 and increasing the External PS to 4.6A

2x 3U 42HP |

2x 3U 84HP |

2x 3U 104HP |

Studio 500 |

Studio 500 |

Studio 700 |

|

|

|

2x 3U 126HP |

2x 3U 168HP |

|

Studio 500 |

Studio 700 |

Top Row : 4HP Power Panel - Power Plate - ED111 Bottom Row : ED123 - ED126 |

|

|

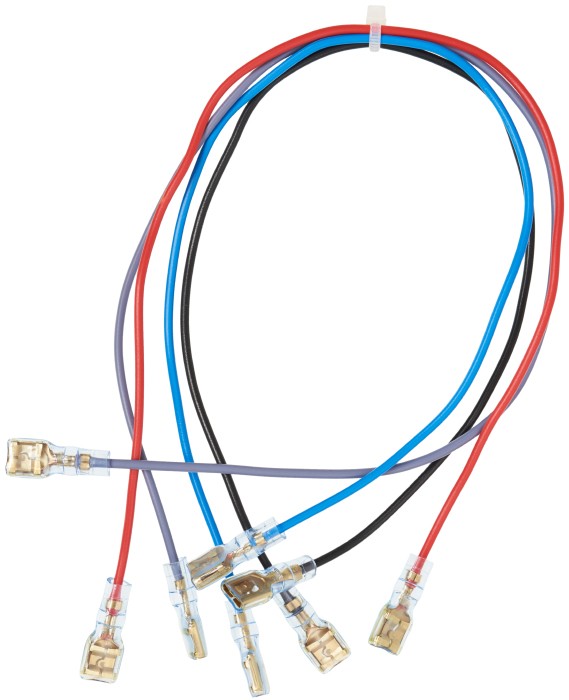

Busboard Cable Set |